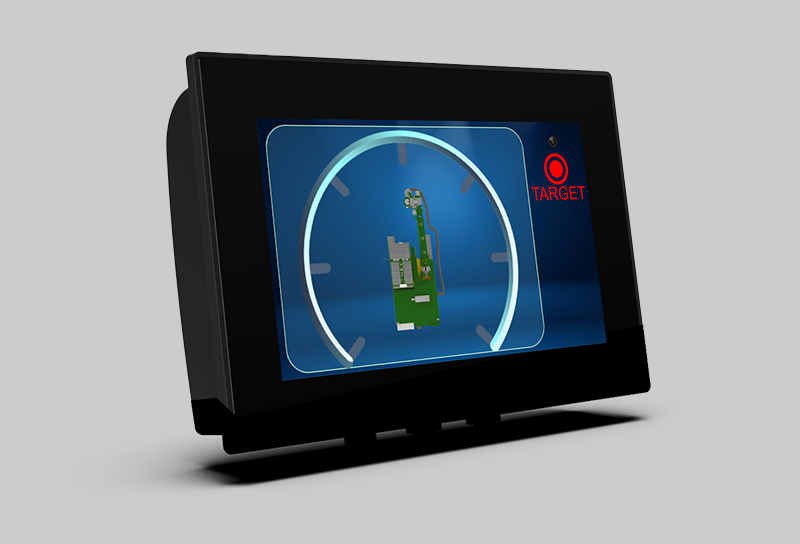

MDS-3700

Real-time drilling operation visualization and operation data consolidation with cloud connectivity.

Xsite Pro 3D Drill

Advanced 3-dimensional drilling system for optimal mining operations.

Positioning Assistance

Real-time machine orientation indication information based on advanced GNSS technology

CHALLENGES regarding blast hole drillings

Machine alignment

Aligning the machine is an additional difficulty in the slope alignment of the drilling arm.

PARALLEL DRILL HOLES

It’s difficult to drill parallel holes, only with marks on the ground.

Exact depth

It’s nearly impossible to drill all holes to the same depth without any measuring system.

High operation costs

The manual measuring causes high operating expenses and is also a huge time factor.

Safety

If the boreholes are drilled in the wrong position, explosions may result in rockfall and a dirty break-off edge.

Drill alignment

It’s difficult to drill all the holes in the same angle.

Solutions

01

MOBA DRILLING SYSTEM FOR ACCURATE & Reliable DRILLING

MDS-3700

MOBA's high-end MDS-3700 drilling system enables you to prepare your opration with precisely measured, uniform drill holes and significantly boost your economic productivity. Save time by eliminating time-consuming manual measurements and drilling parallel holes of the same depth and angle in a matter of seconds with the help of the system. In addition to the remarkable compatibility, you can also benefit from effective and efficient upgrades from a wide range of additional equipment.

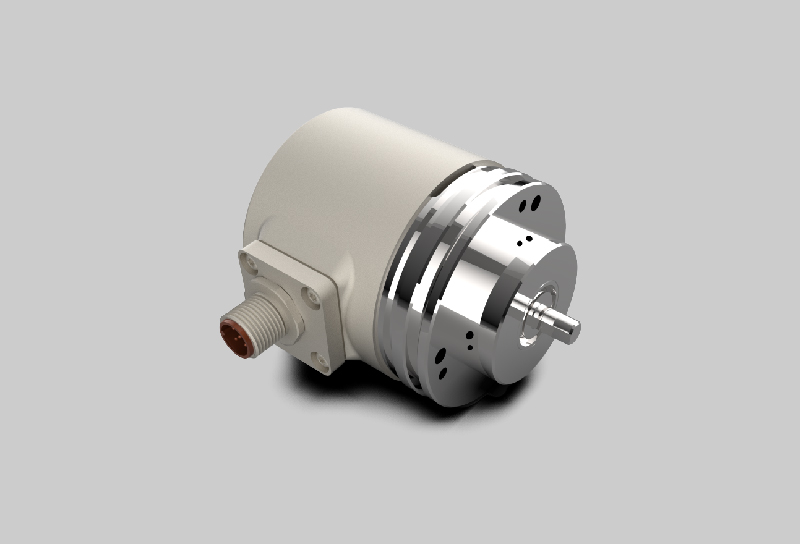

MDS-3700 System components

02

WoRk easier, faster and more safely with 3D drilling

XSITE PRO 3D DRILLING

Xsite PRO 3D drilling eliminates the need for manual marking of the hole starting points in the drilling area, reducing time and eliminating human errors in the process while improving hole quality, dependable and accurate documentation. The Xsite system identifies the hole and assists the operator in quickly and easily providing the desired drilling angles, directions, and depth.

Xsite Pro 3D Drilling System components

03

SPEED UP YOUR DRILLING AND BLASTING PROCESS

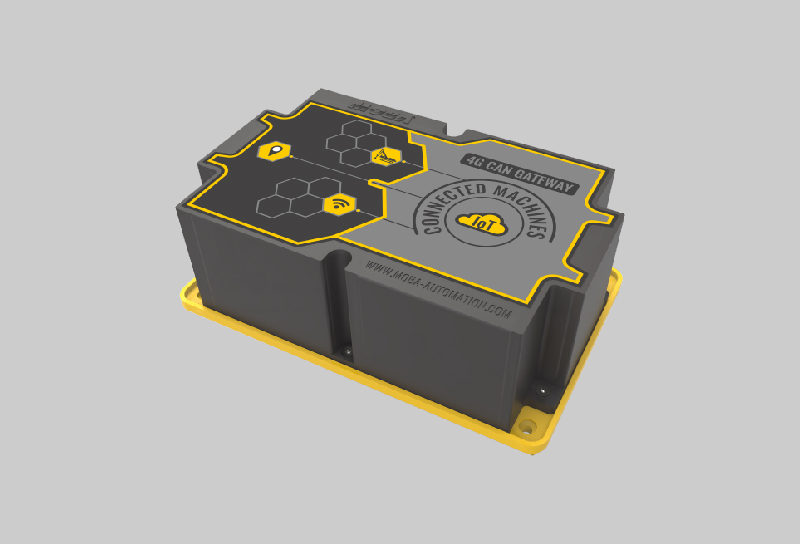

POSITIONING ASSISTANCE

MOBA's GNSS based advanced Drill Hole Positioning & Navigation Guidance System, enables faster positioning/locating of Drill holes. This helps in accurate positioning by eliminating human intervention. Accurate and Fast positioning significantly reduces inproductive time spent for movement and positioning between hole. This reults in improved operational efficiency and cost savings.

MOBA Positioning System is equipped with GNSS antenna and Advanced Display computer, which continuously shows orientation of machine. Display with exteremely user friendly interface continuously guides operator intuitively to align machine to the right orientation at the hole position.

It's possibility of integration with our benchmark MDS 3700 Depth management system further complements overall operational efficiency.