Aligning the machine is an additional difficulty in the slope alignment of the drilling arm.

It’s nearly impossible to drill all holes to the same depth without any measuring system.

If the boreholes are drilled in the wrong position, explosions may result in rockfall and a dirty break-off edge.

It’s difficult to drill parallel holes, only with marks on the ground.

The manual measuring causes high operating expenses and is also a huge time factor.

It’s difficult to drill all the holes in the same angle.

MOBA provides a range of display options, including a fully customised user interface and programmable graphic display. It is designed for harsh environments and supports BS IV and BS VI engines. In bright sunshine, it is readable and can be set display brightness to auto or manual.

Get in touch

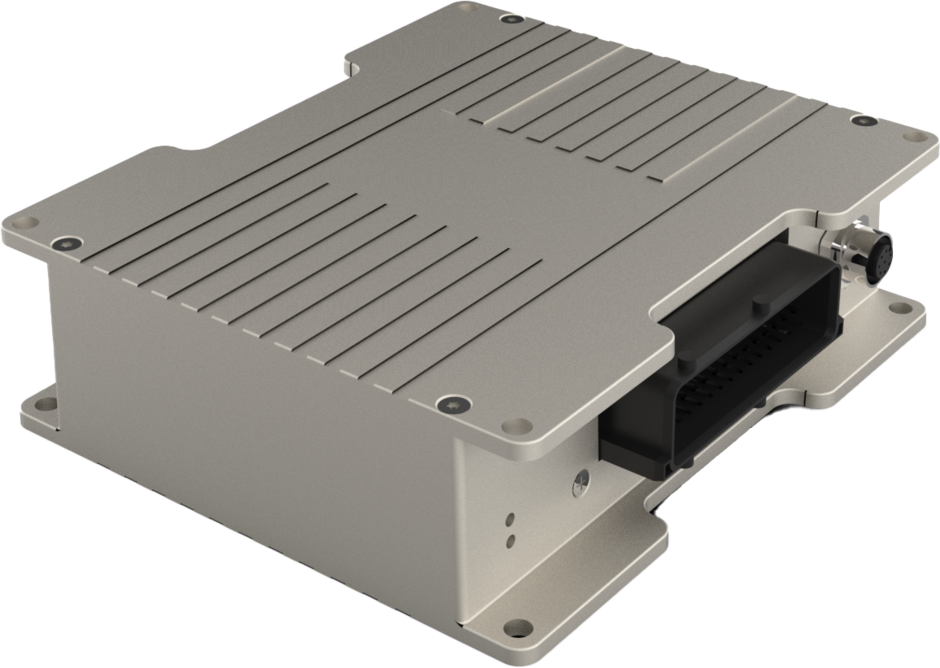

MOBA developed its own machine controller for complex applications in rough and harsh environments. It is a CAN bus communication based on configurable, resistive, digital, analog, and frequency input. The controllers can be compatible and programmable with the CoDesys platform.

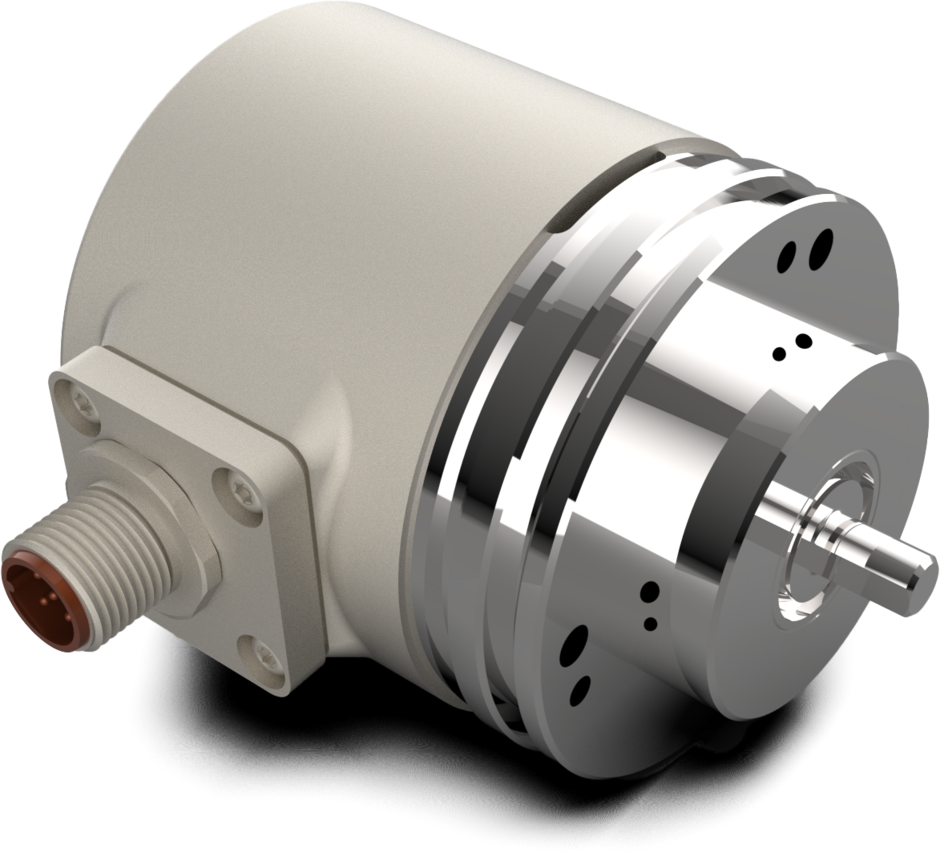

MOBA provides CAN bus communication-based sensors for mobile applications. You can measure machine application parameters such as tilt inclination, slope angle with axis, depth measurement, direction of rotation, vibration, amplitude, and frequency using a moba sensor.

Get in touch

MOBA offers wide range of radio remotes that are available for various applications. These radio remotes have a wide range of receivers and can be customized to suit specific needs. Additionally, the radio remotes are equipped with CAN receivers, which allow for easy integration with machine controllers. The radio remotes can also be used to directly drive proportional valves.

Get in touch

Choose Your Desired MOBA Subsidiary / Language